FEATURED COLLECTION

Discover unbeatable savings in our Featured Section! Get 50% Off our Featured Item and enhance your results with the specially selected add-ons. Each add-on boosts performance in it's own decribed capacity, and together, they deliver the ultimate detailing experience. Grab the Featured Item alone or achieve perfection by adding the complete Featured Collection!

-

Advanced Ceramic Graphene Coating with NANO & NOW UV Technology 🚘

Regular price $59.95 USDRegular priceUnit price per$119.95 USDSale price $59.95 USDSale -

Iron Decontamination "Clay" Cleaning Spray

Regular price $29.95 USDRegular priceUnit price per$0.00 USDSale price $29.95 USD -

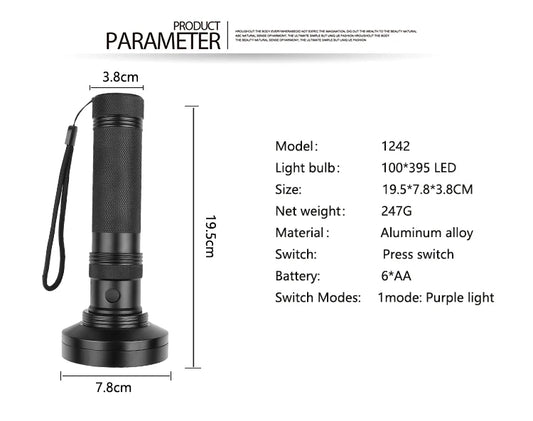

100 LED Ultraviolet Torch, 395nm

Regular price $24.95 USDRegular priceUnit price per$0.00 USDSale price $24.95 USD -

Premium Microfiber Cloth, 40X40CM, 350GSM

Regular price From $13.95 USDRegular priceUnit price per$0.00 USDSale price From $13.95 USD -

IPA Solution/Vehicle Degreaser Spray - Prep for Ceramic Coating

Regular price From $12.95 USDRegular priceUnit price per$0.00 USDSale price From $12.95 USD -

Magic Clay Bar

Regular price $9.99 USDRegular priceUnit price per$0.00 USDSale price $9.99 USD

A FEW benefits: Protection Against

UV Light & Heat (up to 850°F), Scratches and Paint Chips, & Harsh Contaminates

Shield your paint from daily UV exposure, beach and snow salt, and scratches from parking lot carts or neighborhood play. It's not too late to restore or protect your vehicle's vivid paint color, regardless of past or future conditions. Our 10H coating is easier to apply than wax and provides an armored protective shield up to 10 times thicker than most waxes on the market. Make the switch to our trusted ceramic graphene coatings today!

Before 10H Application picture: Toyota Tacoma

Lab Tested & Personally Tested

Any product we offer has been tested on our own vehicles. This picture was taken in the morning and the one below was taken ONLY HOURS LATER....👇📸

AFTER PICTURE: Toyota TACOMA

10H Application Results ☞ ➜

Our reputation speaks for itself, backed by decades of hands-on industry experience. We promise to use our expertise to continually bring you the top-quality products your vehicle deserves!

JUST TRY IT ONCE...

Risk Free, 100% Money Back Guarantee!

Your Order of 1 Bottle Includes:

In the kit you’ll find:

1- 60ml Bottle - Advanced Graphene Ceramic Coating with UV Technology

2- Single Soft Application Towels

2- Suede Removal Towels

1- Suede Applicator

1- Pair of Gloves

Optional 1- UV Flashlight

Instructions for Application: Paint & Glass

1. Prepare your painted surface or glass by using our IPA Solution with our surface prep MicroFiber towel to clean and degrease the surface of any existing protection or residual films. For optimal results, users must Wash, Clay/Decontaminate by using both our Clay Bar and Iron Decontamination “Clay Cleaning Spray” together, and Polish their paint prior to application. If for your paint is “like-new”, or you are simply looking for a better option than outdated wax, then simply use a wash without a wax additive, and move to step 2.

2. Shake the H10 coating bottle before use. Open the coating bottle and begin by dispensing numerous drops of the liquid onto the supplied Micro Silk applicator to sufficiently wet it. Work the product into the surface, ensuring full coverage over the desired area, using cross hatching motions and overlapping your previous pass by 25-50%. During your time between passes, utilize our UV Flashlight for inspections. Take note of between the body lines, bumper areas, mirror caps, and commonly missed areas on your vehicle. To ensure a thorough application, the light should shine and reveal an even and consistent bluish hue of light. If you notice streaking in the surfaces, level out with additional product and the used Micro Silk applicator. These directions will also be included in your shipment.

3. Once the recently applied product begins to characteristically flash and sweat into beads, begin wiping the coating off, applying minimal pressure to the towel in the process. Wipe down in a similar cross hatch pattern as applied, switching/flipping the towel periodically to use a new face to fully level the coating. If you do not have our UV flashlight, by a rule of thumb, apply around ½ of your hood section at a time. Variables such as heat and humidity may cause variations to this stated application size. Our UV Light is recommended.

4. Once fully leveled, allow the coating to fully cure for 24 hours, free from water, elements, or weathering.

Instructions for Application: Plastic Trim & Headlights

2. Open the coating bottle and begin by dispensing numerous drops of the liquid onto the supplied Micro Silk applicator to sufficiently wet it (estimated 10 drops). Work the product into the surface, ensuring full coverage over the desired area, using cross hatching motions and overlapping your previous pass by 25-50%. Since the product is being applied to a porous surface, you will not see a rainbow/ flashing effect - the immediate color change of the plastic or trim will reveal where the product has been applied. However, you are also able to utilize our UV Flashlight for inspections where desired.

3. Once the recently applied product has penetrated, begin leveling the coating, applying minimal pressure to the towel in the process. Wipe down in a similar cross hatch pattern as applied, switching/flipping the towel periodically to use a new face to fully level the coating.

4. Once fully leveled, allow the coating to fully cure for 24 hours, free from water, elements, or weathering.

Instructions for Application: Wheels/RIMS

1. Prepare your wheels by using our IPA Solution with our surface prep MicroFiber towel to clean and degrease the surface of any existing protection or residual films. For heavily contaminated wheels, we recommend a thorough cleaning with a wheel cleaner in addition to Clay/Decontaminate by using both our clay bar and Iron Decontamination “Clay Cleaning Spray” together. This Clay/Decontamination step may be necessary to initially remove stubborn contamination from the barrels and/or wheel faces.

2. Open the coating bottle and begin by dispensing numerous drops of the liquid onto the supplied Micro Silk applicator to sufficiently wet it. Work the product into the surface, ensuring full coverage over the desired area, using cross hatching motions and overlapping your previous pass by 25-50%. During your time between passes, utilize our UV Flashlight for inspections. Take note of behind the spokes, in between the crevices of the wheel design, around the valve stem and center cap areas. To ensure a thorough application, the light should shine and reveal an even and consistent bluish hue of light. If you notice streaking in the surfaces, level out with additional product and the used Micro Silk applicator.

Product Q&A & FAQs

Q&A:

Q: I purchased graphene ceramic coating. If I want to apply a second layer, how long do I let the first one cure?

Answer: We recommend waiting a minimum of 12 hours between coats, but 24 hours is optimal.

Q: To reboost a previously applied Graphene Ceramic coating to remove some containments, should you clay it, or light buff it?

Answer: Claying your ceramic coating every 6-12 months is highly recommended. You will not hurt the finish by doing so, and in fact it is worse for the coating to not clay. By not claying, you are allowing bonded contaminants to slowly eat through the ceramic coating.

Q: I recently purchased your graphene coating kit and would like to know if applying it over PPF is recommended.

Answer: Absolutely! Our ceramic coatings can be applied over the top of a Paint Protection Film

Q: “Can I Apply the Advanced Formula Over My Existing Coating?”

Answer: Yes you can! For a quick installation, you can wipe the vehicle down with our surface prep and then coat it. For a longer lasting, more durable protection we recommend decontaminating the vehicle with clay and or machine polishing prior to applying the new coating. Visit our Featured Collection for details and options.

Q: “Can I layer this product to make it last longer?”

Answer: Yes, of course, but that doesn’t mean layering this product 10 times will make it 10x longer— any application after 3 rounds will render the product redundant and still provide the same hydrophobic effects.

Q: “What is Ceramic Glow Technology?”

Answer: Ceramic Glow Technology™ is a Patent-Pending chemistry. It’s a crystalline form of an optical brightener that absorbs energy and emits light as it relaxes back down to a lower energy state. This will make it easier to avoid missing any areas during the application stage.

Q: “What’s the difference between fluorescence and phosphorescence?”

Answer: Length of time that the light is emitted. Said another way, the amount of time it takes for the electrons to relax and quit releasing energy in the form of photons or light.

Q: “Does the UV Coating act as a durability indicator?”

Answer: No, it doesn’t. It’s currently offered as an application aid and utility for visualizing the coating. Lack of glow does not indicate lack of coating.

Q: “Why does the product glow more intensely on some substrates than others?”

Answer: Differences in porosity and the ability of the coating to penetrate and bond to different surfaces will cause different levels of film thickness. The thicker the film, the more intense the glow typically.

Q: “Will my car glow blue in the sunlight?”

Answer: No, because this coating is completely invisible and clear under standard light, the coating will only glow a bluish hue under the 395 NM UV light.

Q: “Will this coating glow after being “charged” with the UV light?”

Answer: No, since this coating is fluorescent and not phosphorescent, it will excite and glow only when the light is shone. Contrarily, “glow in the dark” items have a yellow/greenish hue from phosphorescent dyes-- these slowly become excited under any light and will diminish over the course of a few minutes.

Q: “What can I use this on? Can I just use this on the whole car?”

Answer: Our Advanced H10 UV Graphene Ceramic Coating provides protection to an extreme range of areas on your vehicle including Painted surfaces, Trim, Bed Rail Covers, Plastic Engine Bay Components, Headlights, Bed liners, - all are safe to be protected.

Q: “What happens if I forget a spot or end up with a high-spot?”

Answer: If you forget a spot and you catch it in time (10-20 minutes after removal) simply reapply to that area and wipe off after 1-2 minutes. Reactivating the product will allow for easier removal. If left on for longer, we recommend Brilliant Glaze and a microfiber applicator, or machine polishing with Correcting Polish to fully remove the imperfection.

Common Sense Warning:

Our Graphene Ceramic Coating™ Advanced is a semi-permanent ceramic coating. Avoid contact with eyes, nose, and ingestion – always keep away from children! If contact does occur, rinse thoroughly with water and monitor for irritation. If irritation persists, contact a physician.